Source: Pexels

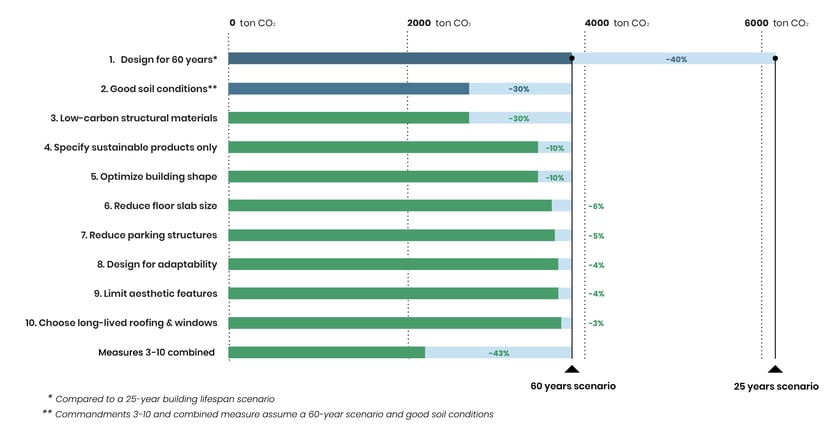

Reducing embodied carbon in buildings is critical to achieving net zero and carbon neutral construction targets. Yet there is much uncertainty about how to reduce embodied carbon. Here, we have distilled some of the most effective approaches into 10 easy-to-follow design rules or commandments.

We created an example baseline building design to quantify the potential impact of adopting these practices. Our baseline design achieved embodied carbon reductions of a third, with potential for cost savings in materials too when retaining traditional structural materials.

Baseline building design

- 7000 m2 (75,350 ft2) office building

- 7 above-ground floors of each 1000 m2 (10,760 ft2)

- 2 underground parking levels

- Precast concrete frame

- 60-year assessment period, assuming that the building would be kept in a condition for leasing to third parties.

Before you start

When you begin working on embodied carbon, make sure that your building has a decent energy performance and whatever low carbon energy supply options your locality can offer. Avoid sites where transport relies on private cars or with long transport distances for users. These provide a solid basis for further decarbonization.

1. Do not build for the short term: ensure demand supports a permanent building

Potential carbon savings* 40-50%

If the service life is limited to 25 years, the annualized materials-driven carbon impacts are 120% higher. If the building can be converted to another use, the impact is reduced even further.

NOTE: for commandments 2-10, we have used a 60-year building lifespan scenario to more accurately depict the impact of each measure.

* In the baseline building

2. Avoid sites requiring soil stabilization and deep foundations

One Click LCA’s Site Designer enables you to assess geotechnical conditions and land use change factors, based on ready-made scenarios. We also offer ready-to-use foundation scenarios for various soil conditions with five-meter depth intervals using different foundation technologies as well as soil stabilization and soil movement prevention.

Potential carbon savings* 30%

The foundations share of embodied carbon impacts is 40% when also considering replacements during life-cycle (not needed for foundations).

NOTE: for commandments 3-10, we have assumed good soil conditions and used a 60-year building lifespan scenario to more accurately depict the impact of each measure.

* In the baseline building

3. Consider structural options: could a lighter or timber frame work?

One Click LCA’s Carbon Designer tool allows users to quickly evaluate the impacts of common structural materials using building geometry.

Potential carbon savings* 30%

The share of embodied carbon impacts for structural materials is always substantial, and in our example building, nearly three quarters.

* In the baseline building

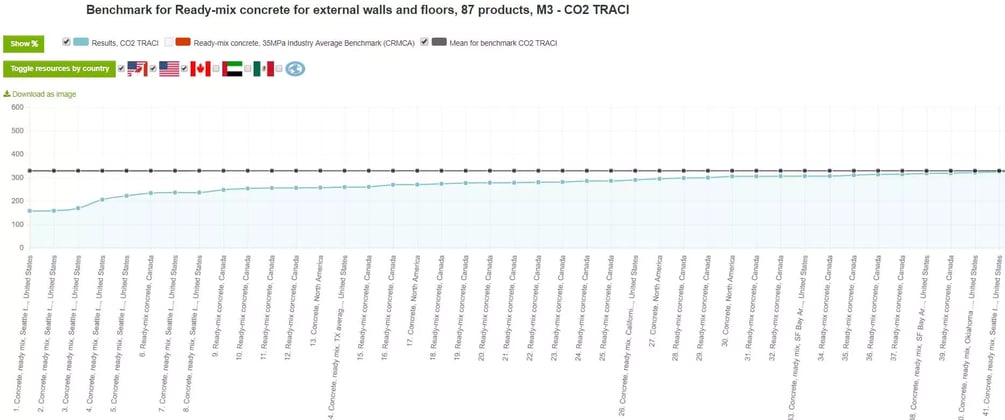

4. Choose low-carbon products: set clear requirements and select the right suppliers

One Click LCA’s materials database contains over 10,000 different construction materials environmental impact profiles for different products, technologies, suppliers and products. There’s also a module to create your own product mixes e.g. for specific concrete recipes, and you can send us any new EPDs that you plan to use if you do not find them in the database.

Potential carbon savings* 10%

In the example building, when structural concretes and steels were changed to lower impact products, the whole building materials life-cycle impacts were reduced by 10%. Looking carefully at what you source can make substantially greater reductions.

* In the baseline building

Example from One Click LCA database: Embodied carbon impacts of concrete range from below 200 to over 500 kg CO2e / m3

5. Optimize the building shape: achieve mass reduction with a compact shape

One Click LCA’s Carbon Designer allows users to consider the impacts of the number of floors, building shape, floor height and additional parameters for the materials demand as well as resulting embodied carbon impacts.

Potential carbon savings* 10%

If the example building were built as a three-storey elongated building, the embodied carbon impacts would be approximately 10% higher. Also, this increases the envelope area, and, as a result, the energy loss via the building envelope.

* In the baseline building

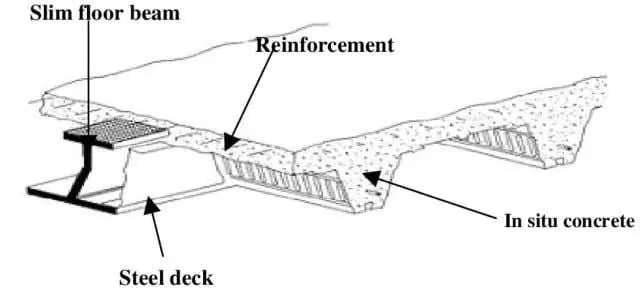

6. Design thinner floor slabs: reduce both slab and envelope material use

One Click LCA’s database includes 50+ pre-built slabs as well as ready-to-use solutions for most innovative beam and deck technologies. A module for creating and calculating your own constructions is also available.

It is also worth noting that having shorter grid spans for columns makes it possible to use lighter and less steel- and cement-intensive slabs. This will have to be balanced against the impact it has on the materials used in the columns and the potential impact on the future adaptability of the spaces. Some types of slab systems also have higher impacts, and care should be paid to the overall design and choice of the floor slabs used.

Potential carbon savings* ~6%

In the example building the share of embodied carbon impacts for all slabs is around 45%. Reducing the net thickness of slabs leads to potential carbon savings of around 6%.

* In the baseline building

7. Do not build separate parking structures: apply parking policies to shift demand

One Click LCA’s Carbon Designer module includes an optional calculation for underground parking floors. Further, operational transport carbon impacts can be accounted for using One Click LCA’s Site Designer.

Potential carbon savings* 4.8%

The share of embodied carbon impacts for parking structures is 7% (in the initial case with the parking mix heavily dependent on private cars). If the initial mix of underground and above-ground parking could be shifted to only above-ground parking places, these impacts would be approximately 69% lower, so an overall potential carbon saving of 4.8%.

* In the baseline building

8. Use movable or refurbishable wall elements to solve space redistribution issues

As floorplan configurations may often change, it is good practice to use reusable and possibly movable internal walls to the extent that they work for the building function. Similarly, electrification that tracks seating arrangements in office buildings. If this practice is not applicable to your project, consider applying construction methods that make it possible to remove the boards intact.

One Click LCA allows you to set the service life for each material to reflect their actually foreseen replacement frequency as well as eventual reuse.

Potential carbon savings* 4%

We have assumed that half of the internal walls in our example building are load-bearing, but that the rest would require rebuilding every decade to fit changing floorplan demands. In this case, the material life-cycle impacts would be around 4% higher, compared to a scenario where wall configuration could remain in place until the material reaches the end of its service life.

* In the baseline building

9. Avoid elements with limited value, e.g. in floorings, ceilings or facades

Potential carbon savings* 4%

The share of embodied carbon impacts for internal ceilings is circa 1%. Furthermore, the building is cladded with an aesthetic steel facing, which has life cycle impacts of around 2%. Avoiding the flooring altogether would achieve impact reductions of around 4%.

* In the baseline building

10. Choose long-lived solutions for windows and roofing

Potential carbon savings* 3%

Depending on your project conditions, specifying longer-lived systems can save both carbon and money. This will be dependent on conditions but can achieve several percentage points of life-cycle embodied carbon reductions – in our example project between extreme cases the difference would be in the order of 3%.

* In the baseline building

These are our top 10 commandments, but there are many more. Including many innovative designs and products or applying some of the following practices:

- Incorporate design for disassembly and other circular economy principles into your design.

- Buy local materials wherever possible to reduce transport impacts.

- Ensure structural material strengths are not generalized but optimized for different uses.

- Reduce waste through careful specification and buying with takeback agreements.

- Consider the longevity of the materials that you use – if it needs to be replaced frequently its impact will be greater.