Image: Enter source or image description here

How to reduce the embodied carbon emissions of your Refurbishment and Retrofit projects

Why we need to address Low Carbon Refurbishment

When talking about Low Carbon Design, much of the attention is focused on New Construction and energy efficiency. However, it is important to also address the issue of existing buildings and their environmental impacts, especially during renovation and replacement of materials. Moreover, it is a mistake to focus only on energy efficiency when it comes to assessing building sustainability. Carbon footprint and other environmental impacts should be taken into consideration within a life-cycle approach. This can help determine whether it would be more sustainable to renovate or demolish and build anew, and also which materials and products should be used to achieve lower emissions over the whole lifecycle. Before addressing how to achieve Low Carbon Refurbishment, we need to clarify why it is important to discuss embodied carbon reduction. Buildings cause 35% of global carbon emissions, and, as the energy grid decarbonizes, it is clear that the next step in climate change action is embodied carbon reduction.

Embodied carbon can be defined as the total of greenhouse gas emissions that are caused by the manufacture and supply of construction products and materials, as well as the construction process itself. By reducing embodied carbon, we can limit the negative impacts on global warming caused by buildings. It is important to note that embodied carbon needs to be addressed in a life-cycle perspective, as results can greatly differ when looking at the short-term or the long-term. It is especially clear that adopting a life-cycle perspective is necessary when looking at retrofit and refurbishment projects, as these highlight the need to upgrade and substitute materials and building components over the years. Each one of these choices has the potential to greatly increase the embodied carbon emissions of the building or make more sustainable choices that will cause less environmental impacts during the whole lifecycle. And it is clear that there is potential to do great good (or harm) when we look at how many old buildings are still in use and go through repaid and maintenance all over Europe. More than 40% of Europe residential buildings have been constructed before the 1960s, and a vast majority of these are not energy efficient [1] To achieve global climate action goals, it is essential to address the impacts caused by buildings, and adopt a lifecycle approach to all embodied carbon impacts, including refurbishment projects.

This article considers the embodied carbon impacts of refurbishments. Refurbishments also can be used to reduce operational carbon by lowering energy or water consumption, or changing energy supply. Energy renovation is not in the scope of this article. When performing refurbishments that combine energy saving measures, appropriate yardstick is the life-cycle carbon – or the sum of operational and embodied carbon of the resulting project.

[1] Reyna, J L and Chester, M V 2015 “The Growth of Urban Building Stock: Unintended Lock‐in and Embedded Environmental Effects”. Journal of Industrial Ecology, 19: 524-537.

The environmental impacts of materials in Refurbishment

During the life cycle of a building, normal tear and wear can affect the performance and aesthetics of a building leading to its refurbishment. Yet, in addition to cleaning and repairing, new requirements by the occupants or owners may lead to fitting new equipment or systems not previously anticipated. In general, the main reasons for which a building will be refurbished and/or retrofitted are:

- Maintenance and repair

- To improve performance (e.g. energy efficiency)

- To change its function

All these possible scenarios involve the disassembly of existing elements and/or the addition of new materials and components. These new materials add to the embodied carbon and other environmental impacts associated with the building. Depending on the type of intervention and how frequent it takes place in the building’s life cycle, these impacts can add significantly to the overall environmental footprint of the building. And, as such, they need to be accounted for. In addition, the frequency and extension of these changes depend on the building type. Whether the property is commercial or residential, additional drivers can influence these changes. For example, commercial properties include office space, retail, industrial (warehouses), and hospitality. They all share a purpose, which is to help businesses generate a profit. So, changes to these installations will include improvements that can help productivity and reduce operating costs. And, because these properties respond to market competition, the changes might take place often, as in the case of retail, where you need to keep abreast of trends and fashion. On the other hand, residential properties change less frequently; its main drivers can be changes in family composition and/or economic incentives to reduce costs (e.g. lower energy costs).

A holistic approach to Low Carbon Refurbishment

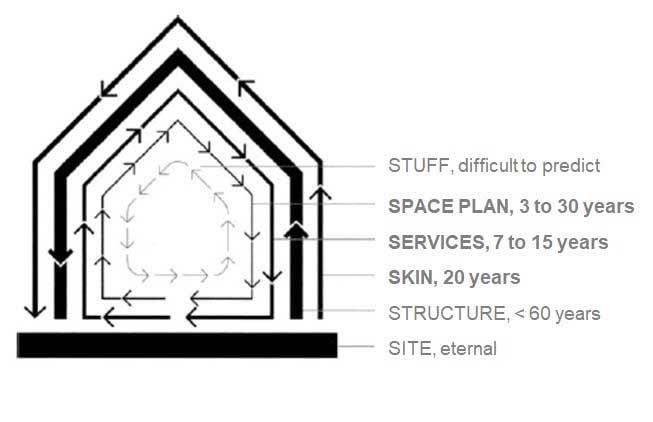

Frank Duffy’s pioneer work in the early 1990s argued that buildings are “…several layers of longevity of built components” [2]. This introduced the idea that building elements changed at different rates based on their function. Originally, Duffy included four layers: shell, services, scenery, and set. Later Brand [2] expanded these into “six shearing layers of change” including the original four (renamed) structure, services, space planning, and stuff, adding site and skin. Each layer has an average service life based on material durability, technological life, and owner’s preference (see Figure 1). Most recently, Arup expanded this into a seventh layer to include (urban) system [3].

[2] Brand, Stuart, 1994. Shearing Layers from How Buildings Learn: What Happens After They’re Built

[3] ARUP, 2016. The Circular Economy in the Built Environment

Figure 1. Shearing (building) layers of change. Conceptual breakdown of different rates of change in building components [2]

Once we consider the reasons for refurbishing/retrofitting and the different rates in which building elements are most likely going to change in time, we help to reduce carbon emissions of these actions through material procurement/use and forward-thinking design.

10 ways to reduce embodied carbon in Refurbishment and Retrofit projects

1. Use low carbon materials and solutions

The most basic strategy requires to use materials that have low embodied carbon. This can be achieved by using:

a. Natural products or those with low energy manufacturing processes. For example, timber or materials with natural fibers come from renewal sources and can be used with low processing. However, remember that adding finishes to protect these materials increases their overall impact. Some varnishes for wood can limit its recyclability and lead to its use as energy source.

b. Materials with recycled content. The impact from raw material extraction is accounted only the first time that material is processed. Afterward, the recycled material includes only the impacts from its reprocessing. This strategy has the added value of keeping the material inside the economy and lowering the pressure for extracting virgin materials.

c. Reuse materials. Similar to using materials with recycled content, reusing materials that still have a service life is another way to reduce new material extraction. The impacts of dismantling those materials and making them fit for reuse can be lower than creating new materials.

One Click LCA’s materials database contains over 10 000 different construction materials environmental impact profiles for different products, technologies, suppliers and products. There’s also a module to create your own product mixes e.g. for specific concrete recipes, and you can send us any new EPDs that you plan to use if you do not find them.

2. Use durable materials for the façade and roof

The building envelope is critical for the energy performance of the building. The retrofit of building elements is one of the major strategies in reducing operational energy consumption. Yet, the façade and roof are under constant wear from natural elements that can lead to frequent repairs and maintenance. By using durable materials, you not only reduce the cost and frequency of refurbishment but also reduce the use of material replacement and its associated carbon footprint.

3. Design façade systems that are easy to maintain

It is not enough that you use durable materials in your façade, you need to be able to service it, and replace elements when necessary. This can only be done when the system can easily be taken apart. In this way, you guarantee

4. Buy local materials

Transportation of materials from the manufacturing facility to the building site adds to the account of your building. By buying from local sources, you are reducing the emissions produced during transportation and support the local economy.

5. Reduce waste with prefabrication and modular elements

The embodied carbon of a building element includes its material footprint and the waste that was generated during its construction. Prefabrication under controlled conditions allows reduction of waste and its associated carbon emissions. Similarly, modular elements permit the efficient use of materials and facilitate the industrialization/prefabrication of these elements.

6. Be mindful when using finishes or decorative façade elements

Finishes have many purposes, as they can help with the acoustics and thermal conditions inside living spaces. They also have an important aesthetic function, that can translate into our overall wellbeing. Yet, they are amongst the elements that have the shortest lifespans in commercial buildings. For example, internal spaces are reconfigured frequently, eliminating partitions and flooring, and changing the ceiling layout. The aggregated impact of replacing these elements several times during the lifecycle of a building can have a significant overall impact. So, finishes should include low-carbon materials, and allow for the easy recovery of those materials for recycling or reuse.

With One Click LCA’s Carbon Designer you can easily compare design options and identify carbon reduction opportunities.

7. Provide flexibility in internal space distribution by concentrating MEP services and using removable partitions

Space planning can benefit from centralized mechanical, electrical, and plumbing services that can easily be branched out to serve the areas based on need. Also, removable partitions make it easier to reconfigure the space for new uses.

8. Consider the life cycle cost of the materials that you use

Cheap now can be quite expensive later as you need to replace more frequently, adding to your operational costs. Also, every time you replace a material, you add carbon emissions to your building account.

One Click LCA offers modules both for Life Cycle Assessment and Life Cycle Costing.

9. Set performance targets to guide your improvement goals

Setting carbon performance requirements or other measures can help you to compare options. And, while the overall goal is finding solutions with lower impacts, these options most perform in a similar fashion to make the comparison valid.

10. Design building elements for disassembly

When possible, the building should be designed to be easily taken apart by sections or as a whole. This reduces the impact on other elements when extracting the building component, and avoids additional wastage. Also, it allows for more efficient recovery of the materials for disposal and this makes it easier to preserve the value of the material for future use.

Key takeaway

The refurbishment or retrofitting of buildings is a necessity in our aging building

Only a life cycle perspective allows you to measure these impacts in time in a holistic way. So, by accounting the embodied carbon, and operational carbon if energy use is impacted, it is possible to measure the trade-offs from environmental and financial perspectives. The key takeaway is that to facilitate the process of refurbishment and retrofitting it is crucial to design the building and its systems for easy disassembly. That way materials can be easily recovered and reused, thus, reducing the extraction of raw materials and preserving the value of the existing ones.

Whether you are working on New Construction or Refurbishment projects, One Click LCA can help you curb your project’s embodied carbon emissions. Get in touch with one of our experts to find out how!