LCA for construction & manufacturing

Easy to use life-cycle assessment & environmental product declaration software with all the world’s data.

Trusted by the world's top firms

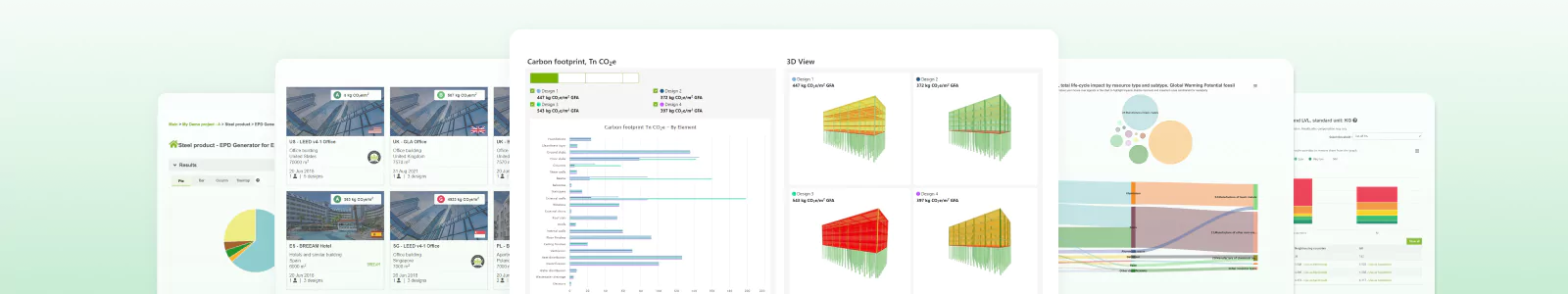

LCA software with all the world’s data & integrations

For design & construction

Design and deliver net-zero and circular buildings. Compare design options and find eco-friendly materials in BIM and the cloud. Differentiate and achieve carbon reductions, building certifications, and regulatory compliance.

For manufacturing

Create, verify, and publish environmental product declarations (EPDs) and assess product carbon footprint and sustainability. Ensure compliance with regulations and client requirements. Win more business by showcasing your product sustainability.

Decarbonize construction & manufacturing

Benefit from One Click LCA’s intuitive, cloud-based software to conduct LCA and generate EPDs at scale. Differentiate with a sustainability edge, win more business, ensure compliance, and reduce costs via automation.

170+

Countries

20+

BIM & other integrations

80+

Compliance standards

200 000+

Qualified LCA datasets

Capabilities

Why One Click LCA?

Largest construction LCA database

Used in 170+ countries, with 200,000+ global up-to-date, verified, supplier-specific, and generic LCA and EPD data points — you can make robust data-driven decisions.

80+ compliance standards

Comply with all national regulations, standards, and certifications. You can also download tailored results to ensure compliance.

20+ BIM & other integrations

Integrate with your existing workflow via BIM and other integrations — or with APIs to bring data seamlessly onboard.

Covers all project phases

Cooperate with project stakeholders across all phases — including pre-project, concept, design, and construction. One Click LCA is with you from start to finish.

Easy, intuitive LCA & EPDs

Clear workflow and process to quantify and reduce carbon across all your project phases. Coherent, reliable data inputs and outputs.

Automated EPD output

You will benefit from a seamless process from templates to publication with EPD Generator, including automated quality checks, verification, and publishing services.

Industries

Decarbonization & sustainability solutions

Contractors

Secure contracts, meet planning requirements, report site impacts, and demonstrate sustainability.

Developers

Get funding and permits, enhance sales and profitability through certifications, ensure returns.

Construction products

Create EPDs, secure market access, differentiate, and grow sales for construction products.

Mechanical & electrical

Decarbonize MEP systems, secure market access, differentiate, and drive sustainability.

Other manufacturing

Product LCA and EPDs for manufactured products, from the simplest to most complex.

Transport & civil infrastructure

Streamline LCA for complex projects with specific infrastructure compliance tools.

Power & utilities infrastructure

Simplify complex life-cycle assessments in the power and utilities infrastructure industry.

Mining & offshore infrastructure

Navigate environmental impacts, compliance, and embodied carbon reporting.

Enterprise

Enterprise-grade LCA tools and expertise to scale teams and meet global demand.

Case studies

Trusted by enterprise — valued by teams

“One Click LCA is powerful and easy to use for building LCA. Their continuous improvement is key in facilitating the wide adoption of LCA by the building industry.”

Nikolaos Vlasopoulos

LCA Services Manager

“Carbon Designer 3D is amazing. We can look into options for reducing carbon very early in the design process, when we don’t even know what the material profile will look like.”

Judhajit (Jude) Chakraborty

Senior Sustainability Consultant

“One Click LCA is the quick and easy way. We appreciate the support service from their LCA experts to discuss modeling approaches and finalize EPDs efficiently.”

Annika Bantle

Applied Sustainability Expert

Talk with an LCA expert

Schedule a demo to get help solving your LCA, EPD, and sustainability needs.