Life-cycle costing tool

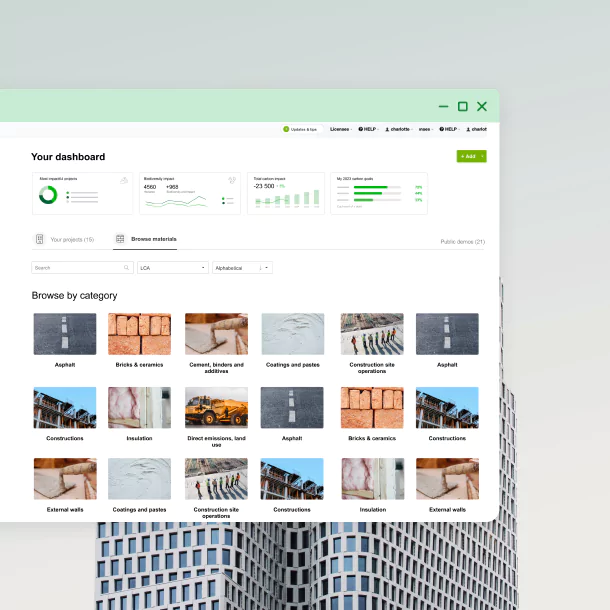

Automate life-cycle costing & carbon

Optimize for the most sustainable and cost-effective design solutions.

Benefits

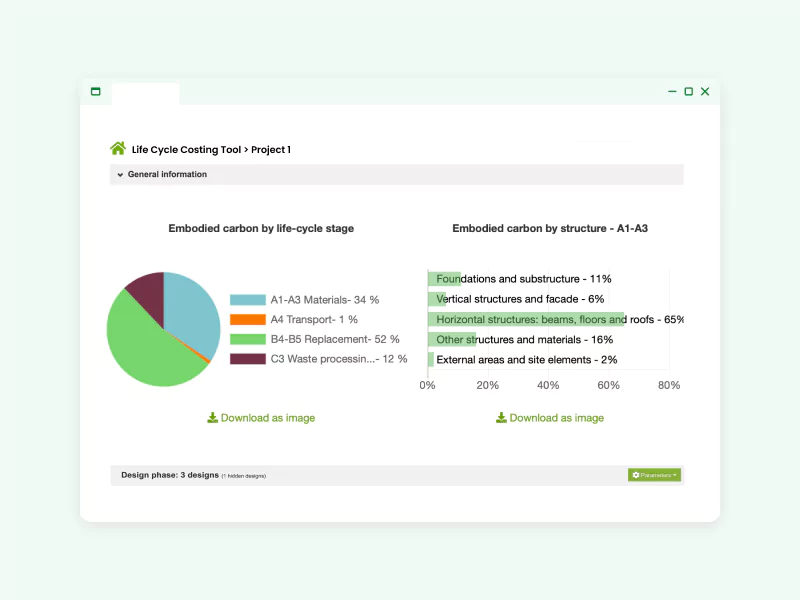

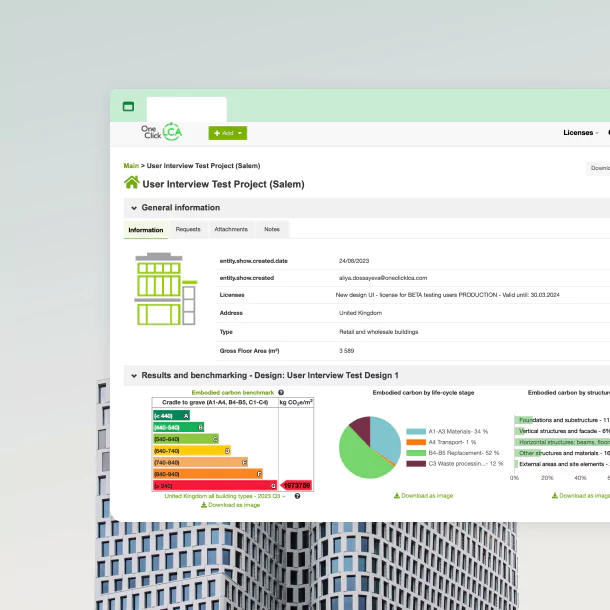

Life-cycle costing made easy

The life-cycle costing tool makes it easy to compare cost and environmental impact across different scenarios.

Easily import materials, generate costs, and compare designs

- Seamlessly import building materials and quantities from Excel, BIM, or energy models.

- Receive automated operation and maintenance costs based on project location.

- Utilize automatic replacement calculations based on material service life.

- Add manual adjustments for project-specific requirements.

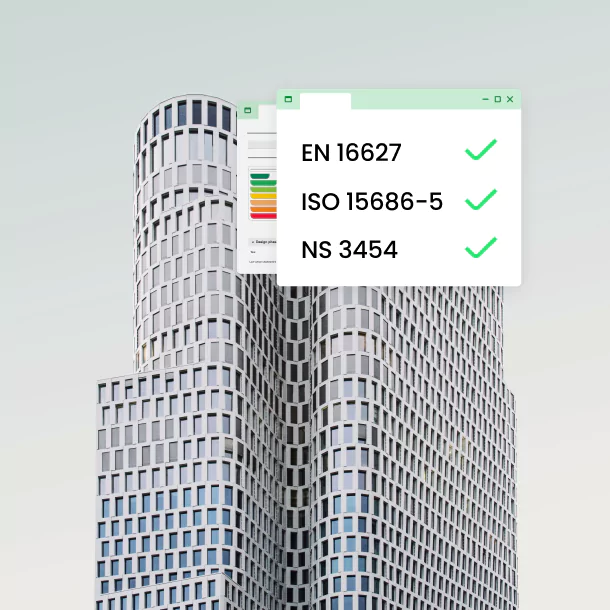

Compliant reporting for informed decisions

- Follow EN 16627, ISO 15686-5 and NS 3454 standards for comprehensive reporting.

- Gain insights into construction, maintenance, operation, and end-of-life costs.

- Make informed choices that balance sustainability and financial considerations.

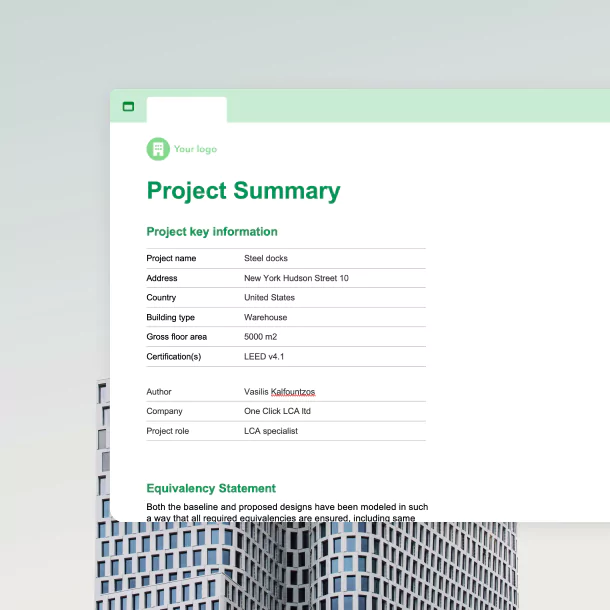

Present clear results for stakeholders

- Utilize a life-cycle costing report template to present findings effectively.

- Submit compliant LCC reports for certification purposes.

Access ready-to-use cost library tailored to your country’s market

- The cost data is available for all main construction materials in the One Click LCA database.

- The database production process has used various cost databases, including the Neubau Baupreise Kompakt; Statistische Baupreise für Positionen mit Kurzttexten (BKI) and the Spon’s Architects’ and Builders’ Price Book (AECOM).

Certifications

Key to green building certifications

Earn BREEAM, LEED & DGNB certification with life-cycle costing and carbon assessments.

Achieve BREEAM — Man 02 credits

You can submit the life-cycle costing results to earn BREEAM – Man 02 credits, including elemental life-cycle cost (2 credits), and component level life-cycle cost (1 credit).

LEED & DGNB

You can utilize your life-cycle costing results to aim for life-cycle costing related credits in LEED and DGNB certification schemes.

RICS Whole Life Carbon Assessment — 2nd Edition

RICS Whole Life Carbon Assessment — 2nd Edition suggests conducting whole-building life-cycle assessments alongside life-cycle costing, aligning with the RICS 'New Rules of Measurement' or International Cost Management Standard for optimal integration.

Frequently asked questions

Life-cycle Costing Tool

What is the purpose of life-cycle costing?

Life-cycle costing analysis (LCCA or LCC for short) is the most accurate way to increase your building’s project savings by comparing different design alternatives. As opposed to more commonly used ROI-based calculations, LCC is conducted based on long-term costs and savings, keeping in mind the fact that they are interconnected. The “life-cycle” part means that LCC assesses all costs that occur over the building’s lifetime, including construction, maintenance, operation, and end-of-life related costs

What are the standards for life-cycle costing?

The standards the LCC methodology refers to are ISO 15686–5, EN 16627, and, for UK, “Standardized method of life-cycle costing for construction procurement” PD 156865:2008 and NS 3454 Lifecycle Costs for Construction NS 3454:2013 Lifecycle Costs for Construction - Principles and Classification for Norway.

What data is available for LCC calculations?

All material data include modifications for different regions related to labor costs and cost indexes. Datasets for material costs are structured to consider the cost of materials installed, and they include a labor cost component. The cost data is available for all main construction materials in the One Click LCA database. Its accuracy will depend on variances in type, specification, and method of construction. The database production process has used various cost databases, including the Neubau Baupreise Kompakt; Statistische Baupreise für Positionen mit Kurzttexten (BKI) (2017) and the Spon’s Architects’ and Builders’ Price Book (AECOM) (2017).

Labor costs are based on the International Labour Organization, wage report 2016. These costs are the total costs paid for labor by the party contracting labor including all applicable overheads.

Maintenance costs are based on regional labor costs and labor intensity of various maintenance operations. The production process has considered various sources, including Whitestone Facility Operations Cost Reference, International (2014) and Whitestone Facility Maintenance and Repair Cost Reference, International (2013) and include modifications for different regions related to labor costs, processes, and cost indexes. End-of-life costs are calculated based on the capital costs. The end-of-life is a percentage of capital costs, which is based on averaged projects.

What are the cost elements included in the assessment scope?

A0-A5 pre-construction and before use stage: Costs of purchase or rental costs (costs of the site); costs of building products; costs related to the transport between factory and site; project feasibility, planning, design, engineering and construction costs, incl. permissions, commissioning and handover; site clearance and landscaping (e.g. lawn, trees, and similar within the curtilage and other external works costs; subsidies and incentives (e.g. incomes related to renewable energy).

B1-B3 operation and maintenance costs: Building-related facility management costs (e.g. regular cleaning, insurance, security, fire inspection, and similar costs); repair costs; ground maintenance; redecoration.

B4-B5 replacement / refurbishment: Planned adaptation or refurbishment (incl. infrastructure, fitting out and commissioning, validation and handover); replacement of major systems and components (incl. associated design and project management).

B6 operational energy use: Energy costs (incl. fuel and electricity for heating, cooling, power, domestic hot water, and lighting, as per the EU’s Energy Performance of Buildings Directive or EPBD).

B7 operational water use: Water-related costs (e.g. rates, local charges, environmental taxes).

C1-C4 deconstruction: Demolition costs; transport costs associated with deconstruction and disposal; fees & taxes (e.g. landfilling); waste processing costs.

What are the differences between 'life-cycle cost, discounted' and the 'life-cycle cost, nominal'?

With One Click LCA's life-cycle costing tool, you can calculate ‘life-cycle cost, discounted’ and ‘life-cycle cost, nominal’ (undiscounted, includes inflation). Both result categories account for the same calculation parameters (the same set inflation rates). However, there is one major difference.

The ‘life-cycle cost, discounted’ does not consider inflation, and the value of the chosen currency is estimated to be the same over the entire set calculation period. The ‘life-cycle cost, nominal’ results include inflation, meaning that the set currency will not have the same value over the entire calculation period, often resulting in a higher total.

What are the advantages and disadvantages of life-cycle costing?

There is not a disadvantage, but an issue that some people see in the LCC approach. It has been noted that LCC focuses exclusively on cost reduction and has no regard for the environmental impact of a building. While it is true that eco-friendly materials can sometimes be more expensive, as technology keeps evolving, new, more ecological materials can prove to be cost-efficient solutions when adopting life-cycle perspective. What is more cost-efficient: installing the conventional HVAC system and consuming a lot of energy over the course of decades or purchasing a contemporary HVAC system that enables net zero building design, producing as much or more energy to cover all expenditure?

When should I conduct life-cycle costing analysis?

LCC should be implemented as early in the project as possible before any major decision has been made. The whole team should be involved in creating alternatives to capture the full potential of your project. LCC should be regarded as an ongoing process and calculations should be repeated several times as the project transitions through construction stages. Our advice is to keep it up to date to ensure accuracy and high-quality analysis.

Automate life-cycle costing & carbon

Talk to our carbon experts and see the software platform in action.